Pre Alloy Ingots

- Home

- Products

- Pre Alloy Ingots

Pre Alloy Ingots

Extrusion Rods Ingots

Our company has taken a significant stride by establishing its own Brass & other Copper Alloys Extrusion plant in year 2010 This strategic move allows us to exercise greater control over the production process and quality standards while catering to the increasing demand for various grades of copper alloy rods, Profiles, Sections, and Ingots.

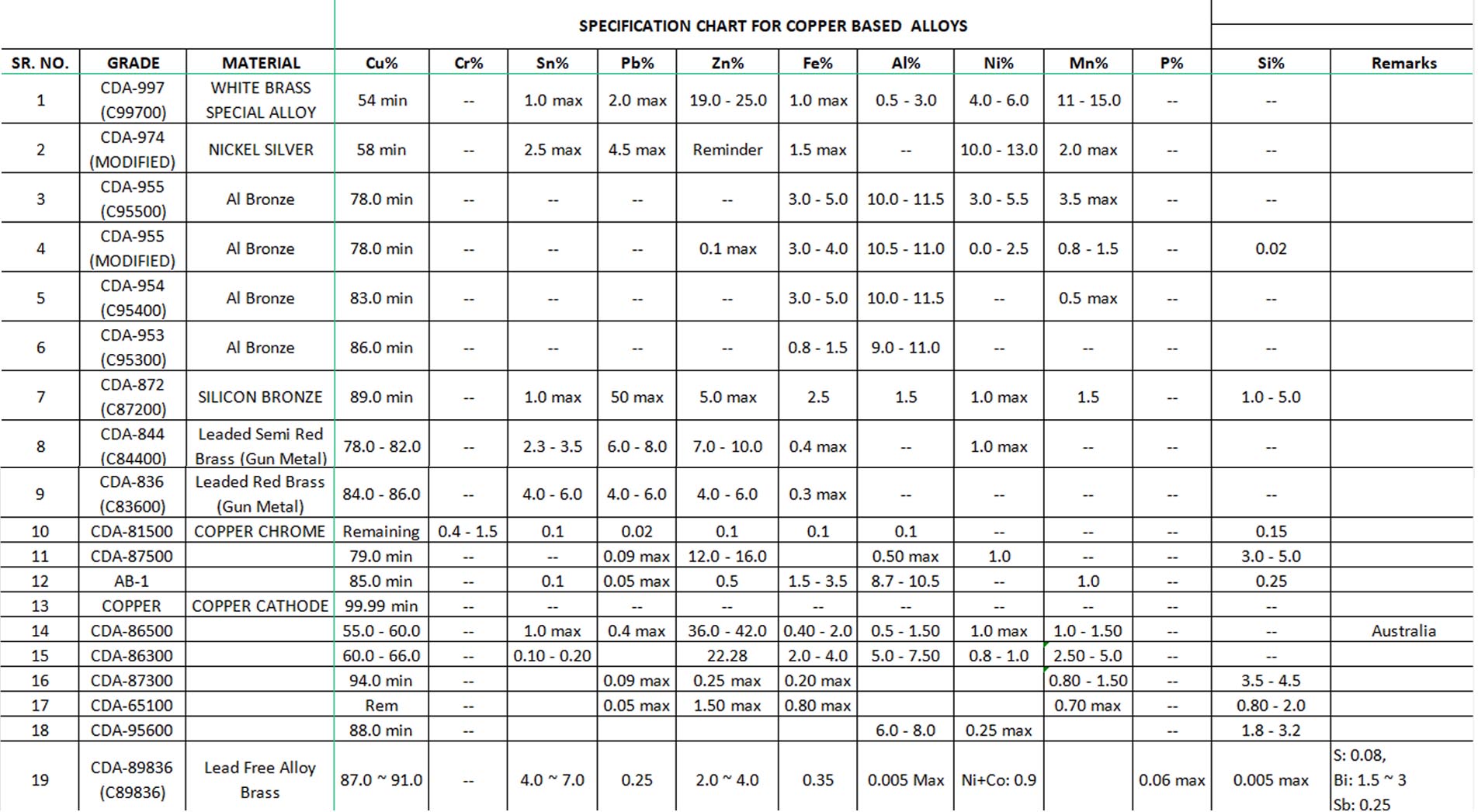

We are producing more than 50+ Different Alloys and 250+ Sizes of Different Brass Sections and Profiles.

Beginning with the import of raw materials, we source the finest copper alloys that form the foundation of our products. These materials undergo quality checks and testing to ensure that they meet our standards. Once verified, our advanced brass extrusion process shapes these alloys into a myriad of forms – from rods and profiles to sections – with precision and consistency.

The journey from extrusion to the final product involves several critical steps, all managed within our facility. Our expertise extends to various electroplating, polishing, and cleaning processes that enhance the aesthetic appeal and durability of our components.

Copper & Alloy Specification Details